Our beers

Copper aleTiger

A local favourite, Tiger is a perfectly balanced beer with carefully selected premium British hops and malt that gives a subtle toffee aroma and a beautiful copper colour in the glass . It's not difficult to see why Tiger is so popular in pubs.

Golden aleSunchaser

Refreshing and zesty, create your 'sunchasing' moment with this beer. A real treat for the senses, with a soft lemon and honey aroma and subtle zesty almost citrus taste in the mouth this is the perfect beer to bring that golden joy all year round.

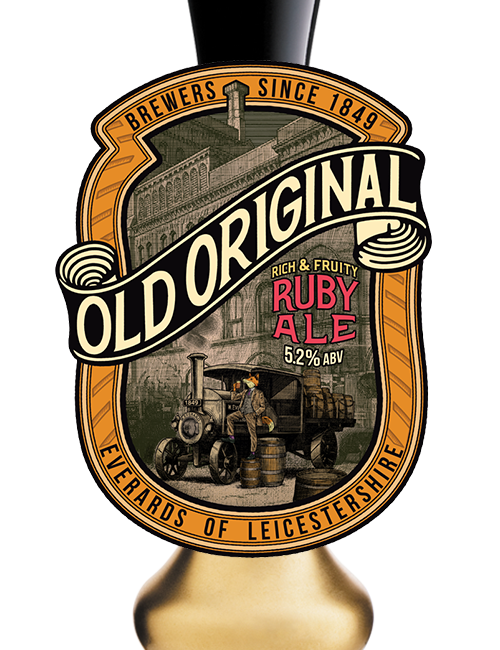

Ruby aleOld Original

The ultimate strong ale with rich and fruity flavours, Old Original is a classic. The very best premium British hops and malt give this ruby coloured beer a full-bodied taste.